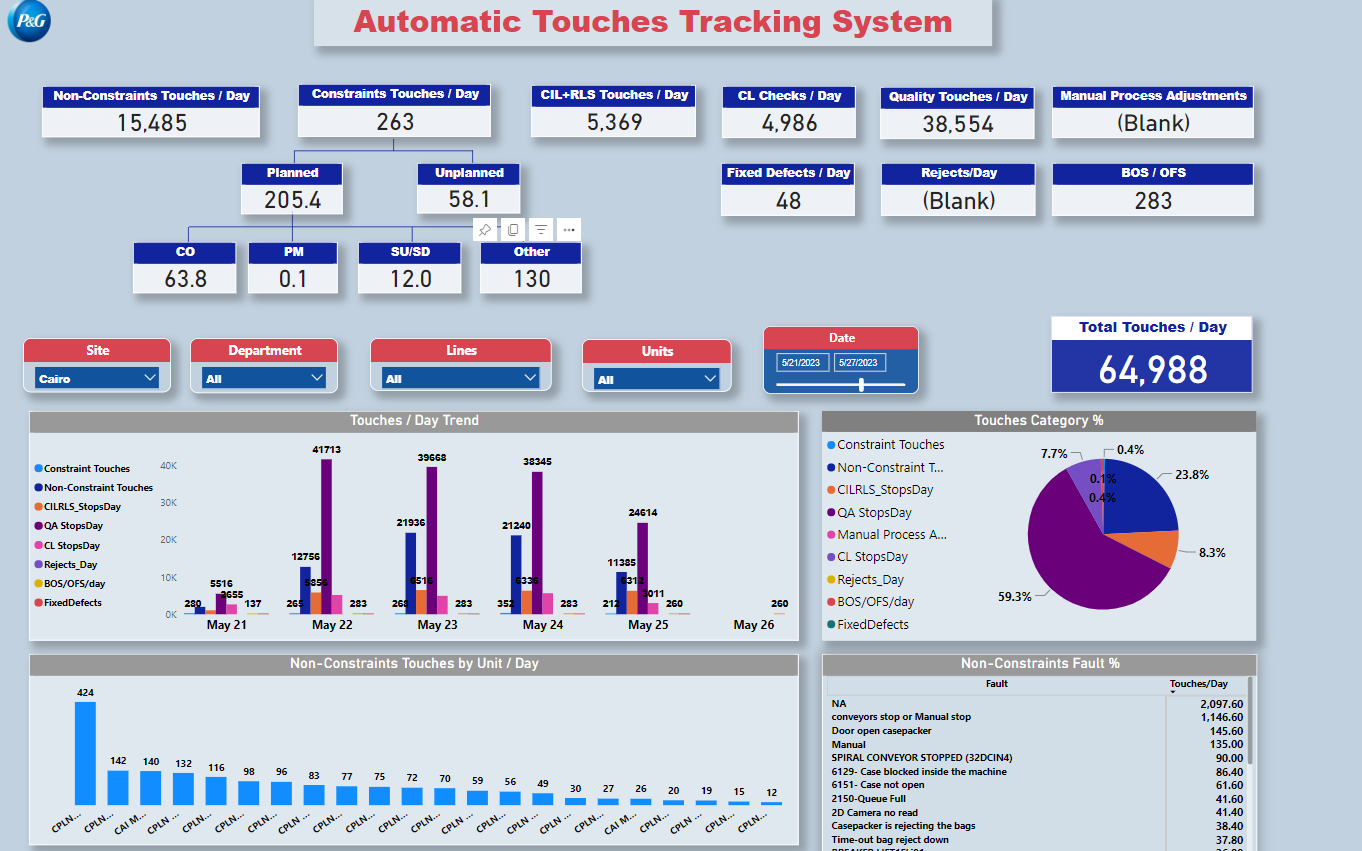

Automatic Touches Tracking System 📈

Welcome to the Automatic Touches Tracking System, a Power BI application designed to help improve manufacturing productivity and drive cost savings. This powerful analytics tool is capable of saving up to $3M in manufacturing productivity expenses by identifying manual touches on production lines and providing insights on how to reduce them. The application is built on SharePoint lists and reads most of its data from an Azure VM, which hosts Python Pandas ETLs that fetch data via REST API from our global MES and stores the data in an SQL Server for Power BI to access.

System Overview 📚

The Automatic Touches Tracking System leverages the following components and services:

- Power BI: The primary visualization and analytics platform

- SharePoint lists: Used for storing and managing metadata

- Azure VM: Hosts Python Pandas ETLs for data processing

- REST API: Provides access to data from the company's global operational data store

- SQL Server: main storage data warehouse for the system

These components work together seamlessly to deliver an efficient and user-friendly analytics tool.

Business Value 💵

The Automatic Touches Tracking System provides significant business value to manufacturing operations by:

- Identifying manual touches: The system detects manual touches occurring on production lines, enabling users to better understand the root causes of inefficiencies.

- Analyzing touchpoints: Extensive analytics capabilities help pinpoint areas where manual touches are most frequent, allowing for targeted improvements.

- Reducing manual touches: By analyzing the data and providing insights, the system guides users in implementing strategies to reduce manual touches and streamline production processes.

- Saving costs: The application ultimately saves up to $3M in manufacturing productivity expenses, including costs associated with both P&G employees and contractors.

Continuous Improvement 🔄

The Automatic Touches Tracking System is designed not only to provide insights but also to support continuous improvement efforts in the manufacturing environment. By regularly monitoring the data and keeping track of the implemented changes, users can quickly identify the impact of their actions and adjust strategies as needed. This iterative approach ensures that manufacturing processes are consistently optimized, resulting in sustained cost savings and improved productivity.

License 📄

Please note that this repository is intended to showcase the capabilities of the system and should not be used as a production-ready solution without further customization and development.